How to prevent mild steel pipe from corrosion in projects

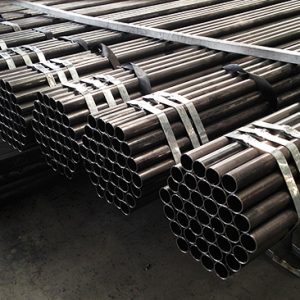

As insiders in the steel industry know, mild steel pipe is one common type of carbon steel pipe in the current steel pipe market. At present, mild steel pipe has been widely used in a variety of applications in production and life. Nevertheless, its structural strength prevents itself from being used for load-bearing girders and structural beams in the construction sector. Basically, the idea of corrosion protection in steel pipe industry comes down to keeping steel pipes from being converted to iron oxide (rust). How to make corrosion protection for mild steel pipes in use is generally to coat the pipe with something that prevents that oxidation reaction from occurring.

Generally speaking, a piping failure is often the first sign of a corrosion problem. Yet in many examples, signs of an impending pipe failure have been evident for months or years, and gone ignored. Failures can be minor or catastrophic, with significant losses due to water damage as well as the cost of pipe replacement. Corrosion has a variety of negative effects on metal. When metal structures suffer from corrosion, they become unsafe and are much likely to cause accidents, such as collapses. Round steel pipe is a very important building material, widely used in the construction field. In the actual procurement, customers tend towards certain strict requirements for the quality assurance of this pipe. In addition, As iron and steel are fragile in the environment, the most popular finish for them is corrosion protection through “galvanizing”. Pre galvanized steel pipe and hot dipped galvanized steel pipe are the two typical types of galvanized steel pipe in the current steel pipe market. Pre galvanizing takes place before the manufacture of the product. This generally results in a better appearance than hot dipped galvanizing process. Hot dipped galvanizing is generally accomplished by two methods, both of which immerse or coat the metal with a liquid zinc bath after various processes. This protective coating is the inter diffusion of zinc and iron and will last for many years. Hot dipped galvanizing should take place after a product has been fabricated, so that all the edges of the material are protected by the galvanic coating. If the product’s galvanic coating becomes scarred or scratched, generally some protection remains as the coating will corrode before the metal.

Dong Peng Bo Da Steel Pipe Group is one of professional steel pipe manufacturers in China. We are committed to providing various types of steel pipes for your choice. Please contact us if you have any requirement.

Tel: +86 18202256900 Email: steel@tjdpbd.com