How to ensure waste reduction strategies

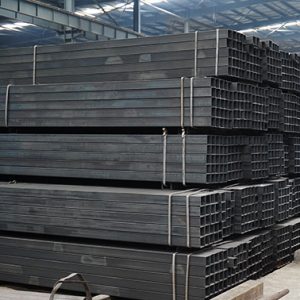

Steel manufacturing is a resource-intensive industry that produces a significant amount of waste. To address the environmental impact of this waste, steel manufacturers need to adopt effective waste reduction strategies. However, implementing these strategies of China hollow section is only the first step. To ensure that these strategies are effective, steel manufacturers need to take several steps.

Set measurable goals: Steel manufacturers should set clear and measurable goals for their waste reduction strategies. This could include reducing the amount of waste generated per unit of production or reducing the overall amount of waste produced. Setting specific targets will help manufacturers track their progress and identify areas where improvements can be made.

Conduct a waste audit: Before implementing any waste reduction strategies, steel manufacturers should conduct a waste audit. This involves identifying the sources and types of waste generated, as well as the quantity of waste produced. By conducting a waste audit, manufacturers can identify areas where waste can be reduced and prioritize their waste reduction efforts.

Involve employees: Waste reduction strategies are most effective when employees are involved in the process. structural steel pipe manufacturer should train their employees on waste reduction techniques and involve them in identifying opportunities for waste reduction. This will help create a culture of waste reduction within the organization and ensure that everyone is committed to the process.

Use technology: Steel manufacturers can use technology to help reduce waste. For example, they can use sensors to monitor production processes and identify areas where waste is being generated. They can also use software to track waste generation and identify areas where improvements can be made. By using technology, manufacturers can optimize their production processes of mild steel tube and reduce waste.

Monitor progress: Steel manufacturers should monitor their progress towards their waste reduction goals. This involves tracking the amount of waste generated and comparing it to the targets set. If the targets are not being met, manufacturers should identify the reasons why and take corrective action.

Continuously improve: Waste reduction is an ongoing process. Steel manufacturers should continuously seek to improve their waste reduction strategies and identify new opportunities for waste reduction. This could involve implementing new technologies, changing production processes of rectangular hollow section, or adopting new waste reduction techniques.

Report on progress: Steel manufacturers should report on their progress towards their waste reduction goals. This could include publishing annual sustainability reports or providing regular updates to stakeholders. By reporting on their progress, manufacturers can demonstrate their commitment to sustainability and build trust with stakeholders.

Tel: +86 18202256900 Email: steel@tjdpbd.com