Environmental considerations

Steel pipe production and supply is a critical aspect of the modern industrial landscape, with applications ranging from oil and gas transportation to infrastructure development. However, the process of manufacturing of welded steel pipe and distributing steel pipes has a significant environmental impact. In this article, we will discuss the key environmental considerations in steel pipe production and supply, and explore potential solutions for minimizing these impacts.

1. Energy Consumption and Greenhouse Gas Emissions

The production of steel pipes involves various energy-intensive processes, such as smelting, rolling, and welding. These processes consume large amounts of electricity and fossil fuels, resulting in the generation of significant greenhouse gas (GHG) emissions. According to the World Steel Association, the steel industry accounts for around 7-9% of global CO2 emissions.

To address this issue, steel pipe manufacturer can adopt energy-efficient technologies and processes, such as the use of electric arc furnaces (EAFs) instead of blast furnaces. EAFs can melt scrap steel, which reduces the need for raw materials and results in lower emissions. Additionally, suppliers can invest in renewable energy sources, such as solar or wind power, to minimize their reliance on fossil fuels.

2. Resource Depletion

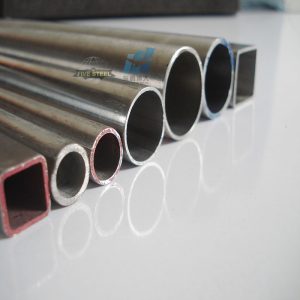

The extraction of raw materials, including iron ore, coal, and limestone, for steel production leads to the depletion of natural resources. This can result in habitat destruction, soil erosion, and water pollution. One way to mitigate resource depletion is to increase the use of recycled steel in pipe production. The steel industry already has a high recycling rate, but further improvements of round steel pipe can be made. By utilizing more recycled steel, manufacturers can reduce their dependence on raw materials, thereby reducing the environmental impact of mining activities.

3. Waste Generation

Steel pipe production results in the generation of various waste products, including slag, dust, and wastewater. These waste materials can have harmful effects on the environment if not properly managed. To minimize waste generation, steel manufacturers can implement waste reduction strategies, such as process optimization and waste recycling. For instance, slag can be processed into construction materials, and dust can be used as a raw material for cement production. Wastewater can also be treated and reused within the production process, reducing the need for freshwater resources.

4. Transportation

The transportation of steel pipes to end-users contributes to air pollution and GHG emissions. This impact can be reduced by optimizing transportation routes of square steel tube and utilizing fuel-efficient vehicles. Additionally, local sourcing of raw materials and finished products can help minimize transportation distances and associated environmental impacts.

Tel: +86 18202256900 Email: steel@tjdpbd.com