How to look at the curtain wall cost in the building field

Along with the global rise in steel costs, curtain wall systems with large panels of stainless steel have increased significantly in cost in recent years. However, as the majority of curtain wall framing tends to be fabricated from extruded aluminium sections, steel structure cost doesn’t have a huge impact on curtain walling. Most contractors are reporting that supplier costs are currently under pressure to maintain overall margins and competitiveness. Take glass curtain wall systems for an example, increases in energy costs for the production of glass in the order of 2% have been passed on to cladding contractors by glass manufacturers. Similar increases are anticipated for all energy-intensive production processes including both aluminium smelters and gasket producers, but these should not result in large increases to tender prices.

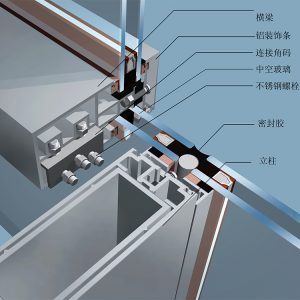

Generally, the flatter the curtain wall system the cheaper it is. Certain costs such as initial system design are fixed and therefore take up a smaller proportion of overall costs in larger projects. The number of systems proposed for any particular project should be minimised as each will have its own design cost and smaller manufacturing runs will mean less room for economies of scale. This will also have a knock-on effect on the installation period as installers work out the best solutions. In addition, the market remains very competitive with tight margins and only small inflationary rises being passed to customers. Materials account for just 30-35% of the total costs of curtain walling, with the remaining costs taken up by design, installation, production and overheads. As a consequence, curtain wall cost is not as sensitive to fluctuations in raw material prices as other forms of cladding materials such as profiled metal decking and sheeting. Another consequence is that any standard system will be considerably cheaper than a bespoke solution, since expensive prototype design and testing will have already been paid for and installation becomes a repetitious but efficient operation.

In addition, curtain wall replacement is a large undertaking after you’ve discovered that your building’s curtain wall is costing you hundreds in utility bills. Unfortunately, it is not a simple repair in the slightest, for it often requires a great deal of disassembly. That means it is costly and time-consuming, as well as disruptive to the occupants of the building. A more affordable, but often under-utilized solution to total replacement of underperforming curtain wall is an interior curtain wall retrofit. Dong Peng Bo Da Steel Pipe Group is a famous steel pipe manufacturer in China. We are committed to providing various types of steel products for your choice in curtain wall building projects. Contact us if you have any need in future.

Tel: +86 18202256900 Email: steel@tjdpbd.com