How to cope with the crack damages of steel pipe in applications

In practical applications, a crack damage of steel pipe is a very common phenomenon, though most professional steel pipe manufacturers have done a good job in manufacturing, testing, or inspection of steel products in a mill. Based on different type of fatigue cracking, it is very important for you to take protective measures to extend the service life of pipeline in use.

In most cases, failure of an operating gas pipeline is a rare event. However, it can not be denied that it is very necessary that care must be exercised to prevent damages to the fracture area in good time to extend the service life of pipeline in use. The techniques for cleaning debris and corrosion products from pipeline fractures include washing with a mild detergent and bristle brush, solvent cleaning and degreasing in an ultrasonic cleaner, replica stripping, and chemical or electrochemical etching in mild or inhibited alkaline or acid solutions. In addition, steel pipe coatings have been used for decades to increase pipeline longevity and integrity as well as to reduce the maintenance costs. Hot dipped galvanized pipe has been considered popular a lot among many users today. The galvanization process protects the steel from rusting damage that can occur during transportation, installation and service. The zinc layer on the surface of pipe can form a barrier protection for steel products to extend the service life in applications.

In modern times, many different surface preparations for steel pipes are employed due to particular requirements of the practical applications in life. For example, steel pipe coatings have been applied to cold rolled steel pipes for decades to increase pipeline longevity and integrity as well as to reduce the maintenance costs. It cannot be denied that the failure of pipelines by external corrosion has caused both financial and environment consequences as well as certain potential safety hazards in use. Furthermore, proper pipe coatings can make the internal field joint welds somewhat more economically attractive to pipeline projects as the corrosion protection helps prevent labor costs, equipment costs and loss of revenue due to corrosion failures over time in use.

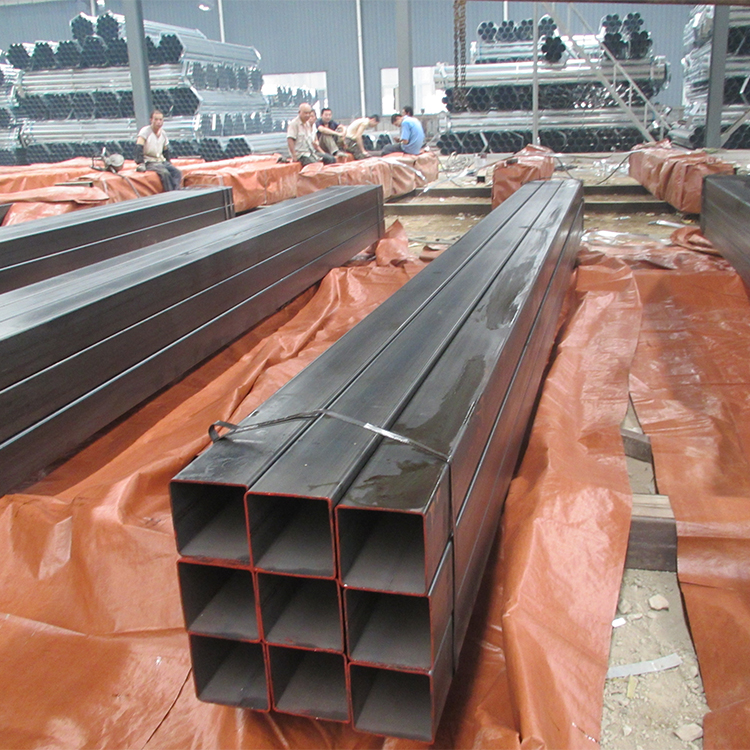

Black steel pipe’s tensile strength makes it a better choice for people to convey water and gas in rural and urban areas. The oil and petroleum industries widely use black steel pipe for convey large quantities of oil through remote areas. It can not be denied that black steel pipe tends to be prone to corrosion in service especially under certain harsh conditions. There are many types of metal surface treatments for black steel pipe in a mill today. For one thing, fabrication services such as metal finishes will generally add to delivery time on your order. For the other thing, a proper coating can become an effective protective film for black steel pipe against any damages or breakdown in order to extend the service life in applications.

Tel: +86 18202256900 Email: steel@tjdpbd.com