Introduction of tube bending

We may adopt the process of tube bending, a form of processing that can be used in industry, design and manufacturing, to reshape tubing or welded steel pipe into a desired type or design. Metal, alloy, as well as steel maybe undergo this process to form construction products and the processes on which can be drawn in tube bending include press bending, rotary bending and roll bending as well. It is the size along with the thickness of the metal that makes the difference in the types of metalworking fits.

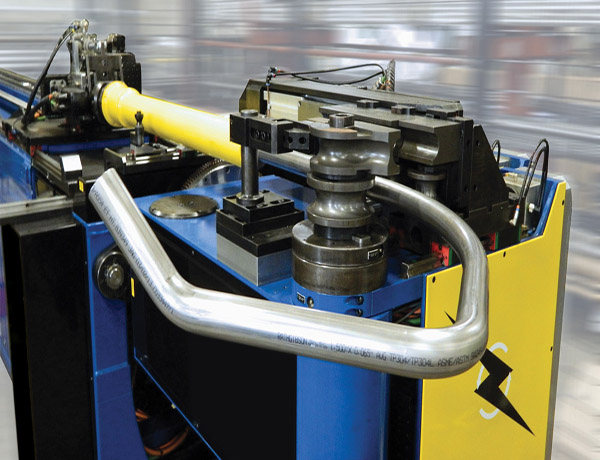

In the process of tube bending, we often use a bending die which works like molds to shape the tubing or cold rolled steel pipe and it can also render a piece of metal 180 degrees, known as U-shaped. Die blocks are used for customizing certain shape for the metal. The metal is clamped into place between two dies by bending then shaping the metal through rotary machine. The rod inserted in tube is used to prevent the pressure which is caused by buckling. The material of the tools is steel and other components can also be used.

We can perform the tube bending in four ways that is pressing bending, rotary press bending, heat induction and roll bending. For press bending, a die is forced onto a tube or square steel pipe. While for the rotary press bending, it can use two types of die which is compressed into each other to form the desired metal. As its name indicated, heat induction can shape the metal by heat which can make tube or pipe more malleable and the method of roll bending is using rollers.

We can adopt particular process depending on several factors that is related to the material to be bent. When the pipes or tubes are cold, they can undergo the process of press bending. If your purpose is creating straight tube or pipes such as rails, car frames, then rotary bending may be a good choice. Under the condition of forming a coil, we can choose the roll bending as a processing method and the heat induction can be applied in bending larger tubes or pipes efficiently. Above preceding discussion, as a steel pipe supplier, we should bend pipes in a feasible way to fully perform the function of products. In our daily life, tube bending is often adopted by contractors and architects to create unique structural designs as well as art sculptures.

Tel: +86 18202256900 Email: steel@tjdpbd.com