technology requirements for welded steel pipe

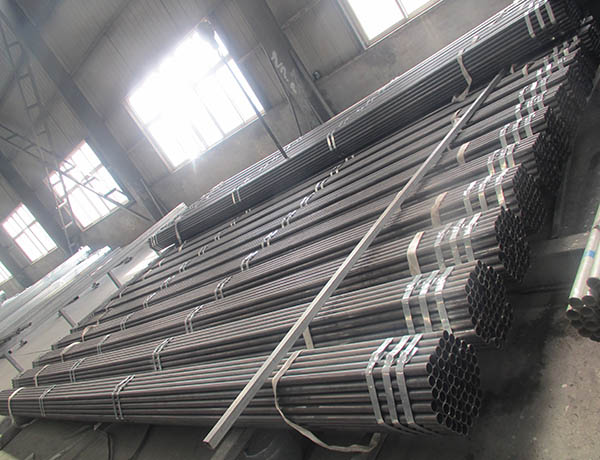

The types of welded steel pipe are related with the application. Different types of black steel pipe are used widely under the condition of development both in technology and in quality which have given full play to the performance of steel pipes in all walks of life. According to the application of various types of steel pipe, we can find that the application of welded steel pipe is more common in our daily life and the effect is also very good and it is a classical choice for customers. What is the technical requirements of this product? Now we will introduce for you simply.

The process is consisted of forging individual metal plates over a mandrel to produce an open-seam pipe and then welding them by pressing them together mechanically. Speaking of cold rolled steel pipe, we can understand it easily because there is a straight line in the welding place. General welded pipe which is made of Q195A, Q215A, Q235A steel is used to transfer low pressure liquid and it can also be made of other mild steel. This kind of welded steel pipe is mainly used in areas such as water, gas and air so the requirements for production technology are very high.

First of all, the square steel pipe uses the quenching tempering processing which possess high standard of heat treatment craft in order to strengthen the depth of hardened layer. The pipe quality will be promoted by this quenching heat treatment which can let it play a better effect. According to GB3092 standard for low pressure fluid conveying in welded steel pipe, the diameter of welded pipe is about 6-150mm, the length of the price is usually 4-10 meters. The surface of steel tube shall be smooth and the folded, crack and lap welding defects are not allowed. Welded steel pipe should be tested for mechanical properties test and flattening test to meet the standard.

Steel pipe should be able to withstand the internal pressure and no leakage in a minute. Depending on the various requirements, we can have a full scan of the pipe to achieve the purpose of inspection. The steel pipe surface treatment is one of the key factors determine the service life of steel pipe. All the steel pipe suppliers make clear that the life of the coating depends on the quality of coating types, coating quality and environmental factors and the quality is very important so we should accordance with the requirements in strict. Please feel free to contact us.

Tel: +86 18202256900 Email: steel@tjdpbd.com