How to use the proper type of conduit in your wire system

When you are ready to start a wiring project in your home, garage, shed, or barn, it seems very important for you first to decide the proper type of conduit pipe for wiring. Generally speaking, the cost of steel conduit installation is higher than other wiring methods due to the cost of materials and labor. In applications such as residential construction, the high degree of physical damage protection may not be required, so the expense of steel conduit is not warranted. Conductors installed within conduit cannot dissipate heat as readily as those installed in open wiring, so the current capacity of each conductor must be reduced (derated) if many are installed in one conduit.

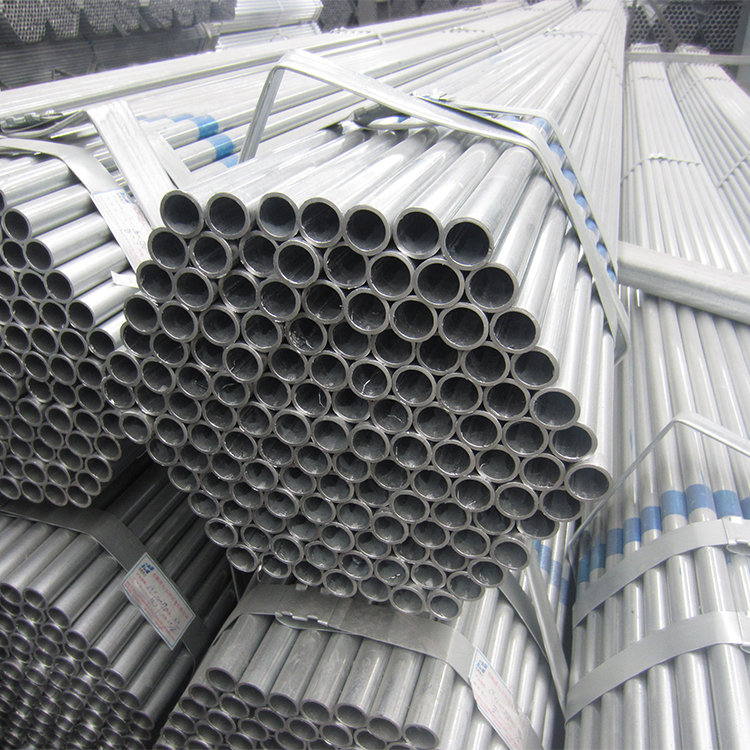

Galvanized steel pipes are very popular in the wire system for a long time. Galvanized steel conduits sometimes serve as a useful bonding conductor for grounding. And wiring regulations may also dictate workmanship standards or supplemental means of grounding for certain types. Some wire has its own sheath coating, requiring only that it be stapled to wall studs and joists to secure it. These types of wires are all enclosed in the same sheath but are not without danger of damage due to contact by anything that can cut into the plastic sheath and wires. For example, mild steel pipes sometimes are widely used as a grounding conductor, and the circuit length is limited. For example, a long run of conduit as grounding conductor may have too high an electrical resistance, and not allow proper operation of overcurrent devices on a fault. As a rule, you will have to choose the steel conduit that both satisfies your needs and is appropriate as per the National Electrical Code.

Conduit systems are classified by the wall thickness, mechanical stiffness, and material used to make the tubing. Materials may be chosen for mechanical protection, corrosion resistance, and overall cost of the installation (labor plus material cost). Wiring regulations for electrical equipment in hazardous areas may require particular types of conduit to be used to provide an approved installation. For example, retail display cases and open-office areas use floor-mounted conduit boxes to connect power and communications cables. In some particular cases, IMC conduit is a thicker conduit such as hot dipped galvanized steel pipe, making it a great choice for outdoor installations against possible corrosion over time. This is also a good choice for exposed walls in basements, garages, outbuildings, and areas the conduit can be hit or damaged.

Tel: +86 18202256900 Email: steel@tjdpbd.com