How to make proper type of powder coating for your welded steel pipe

As a rule, welded steel pipe are prone to corrosion over time in projects. There are many kinds of finishing treatments of corrosion protection in steel pipe industry in order to keep steel products from being converted to iron oxide (rust). Powdering coating is one of the methods available in use today.

What is powder coating?

Powder coating is the application of dry powder paint to a metal part for surface protection. In normal wet paint application the coating is suspended in a liquid carrier that evaporates into the atmosphere leaving the coating protecting the surface. A powder coated part is cleaned and the powder coating is electrostatically charged and sprayed onto the object to be coated. The object is then placed in an oven where the powder coating particles melt to form a continuous film.

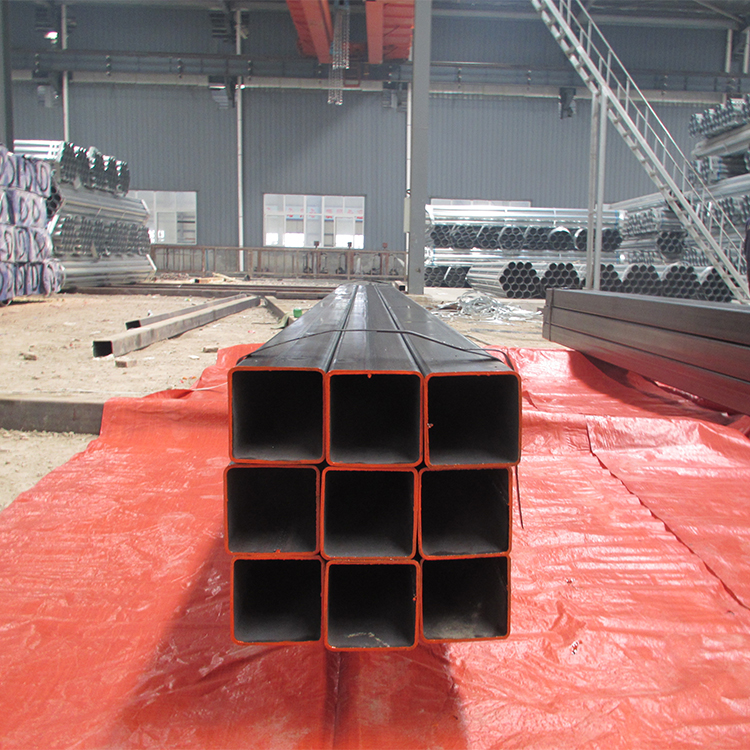

In the current steel pipe market, black steel pipe are very popular in a wide range of applications today. However, the black oxide substance has no capacity of anticorrosion and antirust. In other words, it is necessary to take some measures to protect the black steel pipe from rusting in daily applications. Generally speaking, when powder coated items are installed without damage to the powder coating and they are maintained regularly, they are relatively permanent. The correctly applied coating, although not metallurgically bonded to the metal will not crack, chip or peel as with conventional paint films. During installations, the powder coating should be protected from damage due to abrasion and materials of construction such as mortar and brick cleaning chemicals. Once installed, maintaining the initial appearance of a powder coating is a simple matter. The soot and grime which builds up on surfaces from time to time contains moisture and salts which will adversely affect the powder coating and must be removed. As professional steel pipe manufacturers in China suggest, powder coatings should be washed down regularly (at least once each 6 months in less severe applications and more often in marine and industrial environments). The coating should be washed down with soapy water — use a neutral detergent — and rinsed off with clean water.

In the modern times, UV curable powders are available now and come in different colors and textures. Prices for these powders can still be high, but they enable coating on products previously unresponsive to the procedure. As this technology is new, there are still potential problems associated with it. Yellow colored powders can be difficult to coat and cure at lower temperatures and highly complex three-dimensional parts are also problematic. Are you ready to choose the proper type of powder coating for your structural steel pipe in project right now?

Tel: +86 18202256900 Email: steel@tjdpbd.com