How to make corrosion protection for your steel pipe in use

Basically, the idea of corrosion protection in steel pipe industry comes down to keeping the steel pipes from being converted to iron oxide (rust). How to make corrosion protection for steel pipe is generally to coat the pipe with something that prevents that oxidation reaction from occurring. Galvanizing and painting are the two typical treatment to protect steel pipe from corrosion in use today.

For some steel conduits in electrical applications, there are a number of requirements that detail the length of time that a pipe must be able to withstand being exposed to various corrosive environments without degradation. Regarding other end-use areas, sprinkler pipe, gas transmission pipe, drill casings, drinking water piping and others are also governed by various regulations that address the type of environments those pipes are likely to be exposed to as well as how long the pipe should be able to withstand those environments. For example, the industry requirement for corrosion resistance in electrical conduit is 600 hours of exposure to a saltwater mist without any visible red rust formation on the surface.

As iron and steel are fragile in the environment, the most popular finish for them is corrosion protection through “galvanizing”. Pre galvanized steel pipe and hot dipped galvanized steel pipe are the two typical types of galvanized steel pipe in the current steel pipe market. Pre galvanizing takes place before the manufacture of the product. This generally results in a better appearance than hot dipped galvanizing process. Hot dipped galvanizing is generally accomplished by two methods, both of which immerse or coat the metal with a liquid zinc bath after various processes. This protective coating is the inter diffusion of zinc and iron and will last for many years. Hot dipped galvanizing should take place after a product has been fabricated, so that all the edges of the material are protected by the galvanic coating. If the product’s galvanic coating becomes scarred or scratched, generally some protection remains as the coating will corrode before the metal.

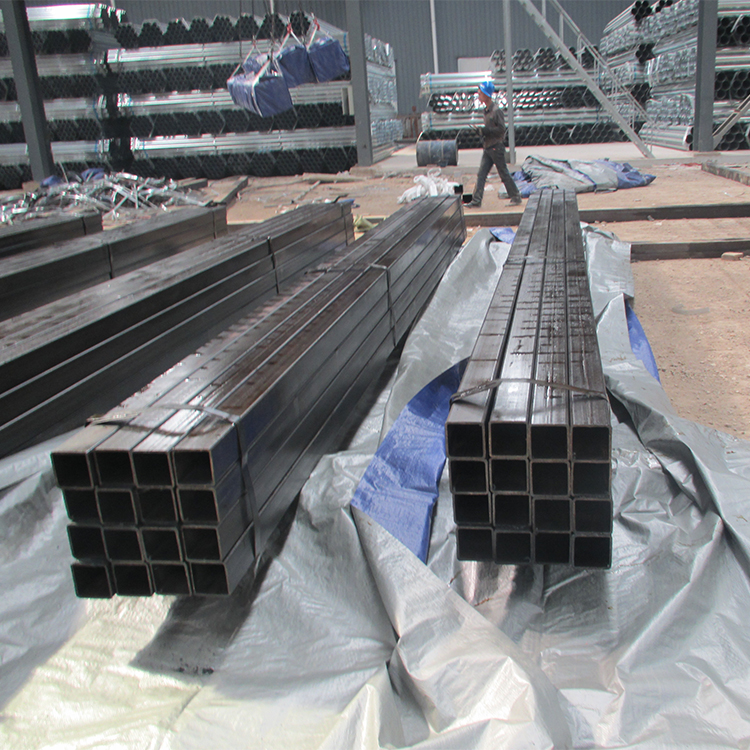

Besides, with regard to the painting treatment for protection corrosion, the surface of steel body is cleaned and then painted flat black. Painted products can be attractive and the paint provides some protection from weather. However, painted surfaces may not be the best choice for high traffic surfaces, as the paint may wear, exposing the metal underneath. If you want a product painted black, specify this in the comments box during the request quote process. DongPengBoDa Steel Pipe Group is one of famous steel pipe manufacturers in China. We are committed to various types of steel pipes for your choice. Please contact us if you have any need in your project.

Tel: +86 18202256900 Email: steel@tjdpbd.com