Cold rolling processing

Cold rolling, a kind of processing method, is used in creating and finishing environments to change the thickness and gauge of metals and it is mostly used in steel mills. The procedure of cold rolling includes threading flattened steel into a machine which can advance the material through a set of rolls and it operates in a continuous loop. Through a consistent rate of speed, these rolls are set apart as it seeks to reach a smaller width than the width of the steel sheeting passed through. The steel, raw material, can be pressed into a ideal gauge for further finishing such as round steel pipe on the basis of going through the cold mill process. The product can reach a desired thickness or shape.

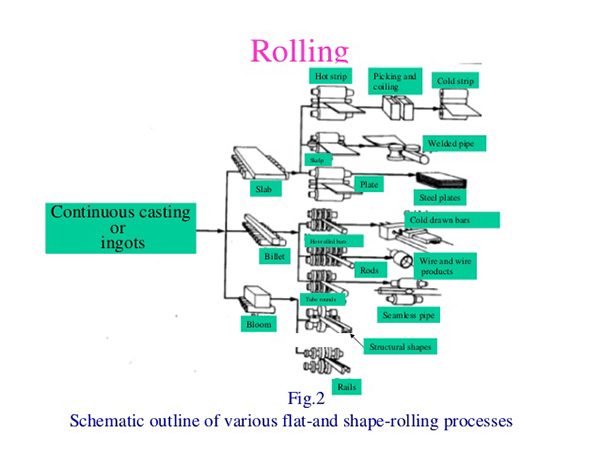

The process of cold rolling which is often along with sparks flying and bright embers burning around steel is probably be seen in workshop. Hot rolling process is a separate step for reducing the rectangular steel tube sizes as well as sheet sizes and hot treatments are the most effective method for manipulating steel mass. While cold rolling can improve the surface condition by refining the metal and it can also make steel more sturdy compared with hot rolling that can make the steel more malleable.

The performance of the steel can be tighten and strengthen through metal-on-metal process. The breakdown or variable patches of the steel which take place in heat processing are built up or annealed when the steel thickness reduced. Speaking of glass manufacturing, its properties can also be changed through multiple processes. Most steel pipe manufacturers in China have long buildings to accommodate their factories or machinery. A coil of steel is threaded through the mill and formed desired gauge and length by rolling process which can begin with a conveyor belt at one end while the other end is a shearing blade.

Steel pipe market always fluctuated because of volatile factors and represents steel pipe prices directly. A strip at first has completed its cycles through the mill then it is cut and moved to another system in which its length, size and other identifying details are recorded. As it seeks to occupy a large share of market, dealers must stand on the point of customers and adopt sophisticated technology. Manufacturing process will be in a position of initiative, creativity and so on by using the cold rolling process. Besides we should also pay close attention to the further processing and requirements to better customer experiences.

Tel: +86 18202256900 Email: steel@tjdpbd.com