Key Differences in Application between ERW and Seamless Square&Rectangular Tubes

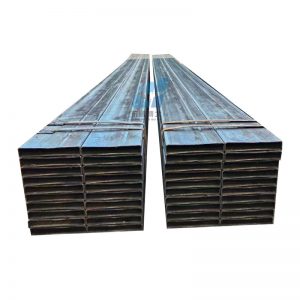

This is a practical and important question in the fields of construction and industry. Although they may appear similar externally, ERW Square and Rectangular Tube and seamless square/rectangular tubes have distinct differences in performance, cost, and application due to their fundamental differences in manufacturing processes.

In short, the core difference lies in the presence or absence of a “seam,”which directly determines their pressure-bearing capacity, uniformity, and price. The following is a detailed comparison of their applications.

Summary of Core Differences

| Feature | ERW (Electric Resistance Welded) / LSAW Square & Rectangular Tube | Seamless Square & Rectangular Tube |

| Manufacturing Process | Formed by rolling and welding steel plate (has one longitudinal weld seam) | Formed by piercing, rolling, or extruding a round steel billet (no weld seam) |

| Key Advantages | Cost-effective, high dimensional accuracy, uniform wall thickness, can be produced in large sizes | High pressure-bearing capacity, excellent overall uniformity, no welded weak points |

| Main Disadvantages | Existence of a heat-affected zone along the weld, theoretically a potential weak point | Expensive, potential wall thickness variation (due to centrifugal force during manufacturing), size limitations |

| Primary Application Guidance | Structural support, general load-bearing applications | High-pressure, high-stress, critical safety applications |

Main Applications of ERW Square and Rectangular Tubes

Due to their excellent cost-performance ratio and good mechanical properties, ERW tubes dominate the vast majority of conventional application markets.

1. Building and Steel Structure Sector (Primary Market)

Framework Structures:Columns, beams, and trusses for factory buildings, stadiums, exhibition halls, and commercial complexes. Used as primary load-bearing and supporting members.

Space Frame Structures: Members for spatial grid structures.

Curtain Wall Mullions: Used as support frameworks for glass or metal curtain walls, requiring high precision and a flat appearance.

Staircases, Guardrails, Canopies:For architectural decoration and secondary structures.

2. Machinery Manufacturing and Vehicle Sector

Machine Frames:Frames for machine tools, production lines, storage racks, etc.

Vehicle Components:Truck chassis frames, bus body skeletons, support structures for agricultural machinery, and other non-high-pressure fluid components.

3. Infrastructure and General Engineering

Bridge Auxiliary Structures:Pedestrian overpasses, bridge guardrails, etc.

Tower and Mast Structures:Non-primary pressure-bearing parts of communication towers and lighting poles.

Reason for Use:In these fields, structures primarily endure stresses like tension, compression, and bending, where extreme uniform pressure-bearing capability is not required. ERW tubes fully meet the strength requirements, offer significant cost advantages, and are easier to process (cutting, drilling, welding).

Main Applications of Seamless Square and Rectangular Tubes

Seamless tubes are primarily used in critical areas demanding high safety factors and harsh operating conditions due to their weld-free nature and high strength. It is worth noting that both seamless and welded tubes can be further processed into cold rolled square and rectangular hollow section for applications requiring tighter dimensional tolerances and smoother surfaces.

1. High-Pressure Fluid Transmission and Pressure Vessels

Special Piping Systems:Used for pipe supports or structural parts in systems conveying high-pressure steam, high-pressure gases, or flammable/explosive fluids (e.g., in petroleum cracking plants). While the pipelines themselves are often circular tubes, their critical support structures may utilize seamless square/rectangular tubes.

Pressure Vessel Frameworks:External support frames for boilers, reactors, and other high-pressure vessels.

2. Heavy Machinery and Critical Load-Bearing Components

Construction Machinery:Core load-bearing components of excavators, cranes, and crawler cranes—such as booms, outriggers, and chassis frames—that withstand enormous alternating impact loads. Failure in these parts can have severe consequences, necessitating the use of seamless tubes for absolute reliability.

Hydraulic Cylinders and Servo Mechanisms:Used as housings for high-performance hydraulic cylinders or critical links in servo mechanisms.

3. Aerospace, Defense, and High-Tech Equipment

Used in auxiliary structures for aircraft landing gear, missile launchers, radar mounts, and other fields with extremely high demands for material uniformity and reliability. (These often involve special alloy seamless tubes.)

4. High-Stress Structural Joints

In critical load-bearing joints of large stadiums, skyscrapers, or bridges, where calculations indicate exceptionally high stress concentration and the heat-affected zone of a weld could pose a risk, seamless square/rectangular tubes may be specified locally. For some structural applications requiring specific strength and toughness profiles, manufacturers may opt for hot-rolled square and rectangular hollow section as the starting material.

Reason for Use:In these applications, materials must withstand extremely high internal pressure, fatigue stress, or impact loads. Any weld seam can become a point of stress concentration and a potential source of fatigue cracks. The “integrity” of seamless tubes eliminates this risk, providing a higher safety margin.

Conclusion and Selection Advice

Choose ERW Square and Rectangular Tubes when:

The project is budget-sensitive, and cost control is important.

They are used for general building structures, frameworks, or supports with clear and stable load conditions.

High dimensional accuracy and appearance are important (e.g., for curtain walls).

The operating environment does not involve extreme pressure, temperature, or fatigue loads.

Choose Seamless Square and Rectangular Tubes when:

The application involves high pressure, life safety, or critical equipment.

The component will endure severe impact or high-frequency fatigue loads (e.g., crane booms).

Design codes or clients explicitly require the use of seamless tubes.

The conveyed medium is highly hazardous, making leakage risk unacceptable.

Simple Rule of Thumb: Consider “Force” and “Risk.”

Use ERW for conventional “static” and “general” load-bearing (the cost-effective choice).

Use seamless for exceptional “dynamic,” “high-pressure,” and “high-risk” applications (the safety-critical choice).

Tel: +86 18202256900 Email: steel@tjdpbd.com