How to correctly join welded steel pipe in construction projects

So far, welded steel pipe has been widely used as building materials in construction projects for a long history. For the one thing, welded steel pipe remains much cost effective compared with many other construction materials for over more than 30 years. For the other thing, welded steel pipe used as one kind of structural frames is considered an environment friendly building material in construction industry. However, welded steel pipe joining is an extremely labor-intensive and costly process in most construction projects today. Do you really know how to correctly join your welded steel pipe in applications?

As a rule, piping encompasses six different tasks: lifting, joining, aligning, inspecting, transporting of materials, and procurement. Of these, joining is the most important, consuming 25 percent of the cycle time and requiring a greater degree of skill than any of the other five tasks. And most of the problems associated with piping, however, are related to the field of welding. First of all, the selection of materials for pipe is a process that requires consideration of material characteristics appropriate to the specific application at hand. At this time, how to select the proper type of structural steel pipe applied in construction projects would be the first important thing before you will start your work in projects. Once you apply the desired structural material in construction projects, the choice of methods of pipe joining would be the next important step. Generally, how to correctly join your steel products depends on a variety of factors, such as pipe diameter, pipe material, pressure rating, and other service requirements. Welding can be used to join pipes of any diameter and is a leak-proof method. However, considering the shortage of highly skilled welders, welding is somewhat limited. Stick welding is the most popular method in use in the construction industry today. And it is steel dominant because there has been considerable reluctance on the part of welders in the various construction trades to use other methods.

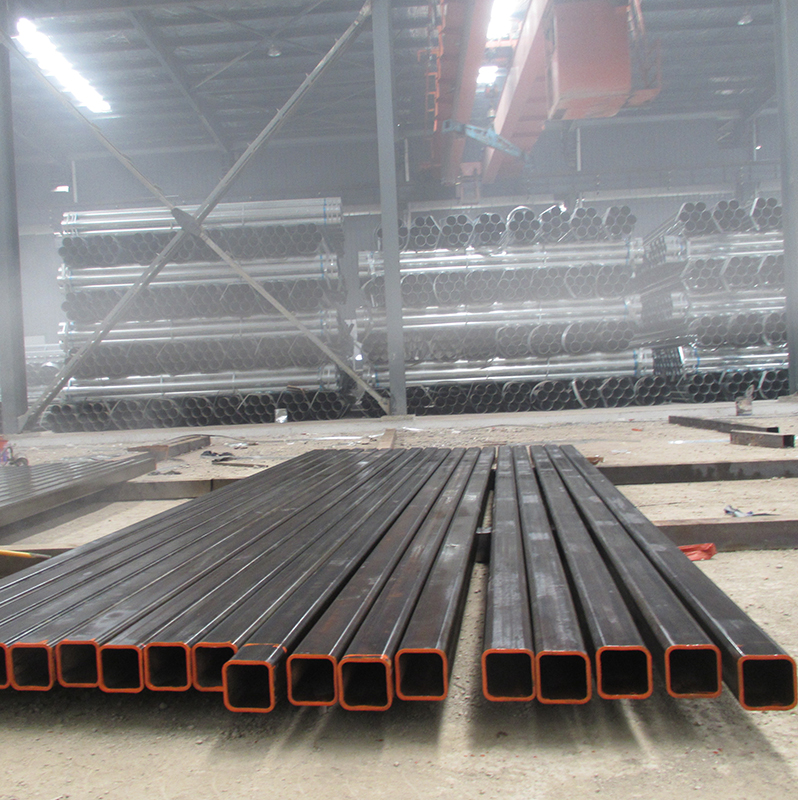

Steel is very flexible, and easy to modify and customize according to your personal preference. It also has this natural beauty praised by many architects which makes them more excited to work with steel compared to other materials. Sometimes, black steel pipe is chosen for structural frame in construction projects, which offers good strength and is relatively inexpensive compared with other steel materials in the market. However, its use is limited to some non-corrosive applications. As a rule, each project is judged on its use of structural steel from both an architectural and structural engineering perspective. For example, pre galvanized steel pipe is easy to expose the building’s beauty in a design that will emphasize its grace, strength, transparency, and slenderness. The column-free clear spans and the use of colored steel pipe coatings bring out the natural lighting of the frame and its simple elegance. In the construction activities, mechanical joining is another popular method to join your steel products, for this method is generally effective and uncomplicated, and little mechanical skill is need. Its use is limited, however, because it can be applied only to the joining of thick pipe.

Tel: +86 18202256900 Email: steel@tjdpbd.com