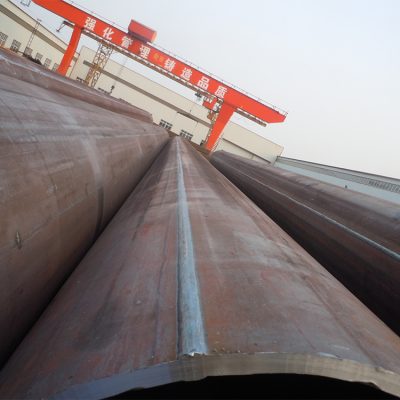

API 5L Steel Pipes/ Line Pipes

TIME:2019-03-08

Brief introductionWe can supplier API 5L Steel Pipes/ Line Pipes.

High quality and Widely used in construction.

We have a series of practically complete pipe specifications for your choice.

API 5L Steel Pipes/ Line Pipes

1.Short Description:API steel pipe mainly refer to the steel pipes (ERW/SSAW/LSAW/seamless) meets the request of standard API 5L psl1/psl2(ISO3183), used for natural oil/gas or how pressure fluid transmission.

2.Welded Type: ERW, SSAW, LSAW/Seamless

3.Sizes:

ERW: 1/2″ to 26″ Length:4 to 12 meters

Seamless: 1/2″ to 24″ Length: 5 to 12 meters

SSAW: 8″ to 120″ Length:4 to 28 meters

LSAW: 12″ to 72″ Length:4 to 13.5 meters

4.Standard:API 5L psl1/Psl2, ISO3183, GB/T9711.1 and 2

5.Steel Grade:Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70

6.Surface:Fusion Bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement.

7.Test:Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test, X-ray Test.

8.Mill Test Certificate:EN 10204/3.1B

9.Chemical Composition See table A1/A2

| A1 | |||||||||

| Chemical composition for PSL1 steel pipe | |||||||||

| Steel Grade | Heat Analyses max. for welded | Steel Grade | Heat Analyses max. for seamless | ||||||

| C | Mn | P | S | C | Mn | P | S | ||

| L210/A | 0.22 | 0.9 | 0.03 | 0.03 | L210/A | 0.22 | 0.9 | 0.03 | 0.03 |

| L245/B | 0.28 | 1.2 | 0.03 | 0.03 | L245/B | 0.26 | 1.2 | 0.03 | 0.03 |

| L290/X42 | 0.28 | 1.3 | 0.03 | 0.03 | L290/X42 | 0.26 | 1.3 | 0.03 | 0.03 |

| L320/X46 | 0.28 | 1.4 | 0.03 | 0.03 | L320/X46 | 0.26 | 1.4 | 0.03 | 0.03 |

| L360/X52 | 0.28 | 1.4 | 0.03 | 0.03 | L360/X52 | 0.26 | 1.4 | 0.03 | 0.03 |

| L390/X56 | 0.28 | 1.4 | 0.03 | 0.03 | L390/X56 | 0.26 | 1.4 | 0.03 | 0.03 |

| L415/X60 | 0.28 | 1.4 | 0.03 | 0.03 | L415/X60 | 0.26 | 1.4 | 0.03 | 0.03 |

| L450/X65 | 0.28 | 1.4 | 0.03 | 0.03 | L450/X65 | 0.26 | 1.45 | 0.03 | 0.03 |

| L485/X70 | 0.28 | 1.4 | 0.03 | 0.03 | L485/X70 | 0.26 | 1.65 | 0.03 | 0.03 |

| A2 | |||||

| Chemical composition for PSL2 steel pipe | |||||

| Steel Grade | Heat Analyses max. for welded & Seamless | ||||

| C | Si | Mn | P | S | |

| L245R/BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 |

| L290R/X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 |

| L245N/BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 |

| L290N/X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 |

| L320N/X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 |

| L360N/X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 |

| L390N/X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 |

| L415N/X60N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 |

| L245Q/BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 |

| L290Q/X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 |

| L320Q/X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 |

| L360Q/X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 |

| L390Q/X56Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 |

| L415Q/X60Q | 0.18 | 0.45 | 1.7 | 0.025 | 0.015 |

| L450Q/X65Q | 0.18 | 0.45 | 1.7 | 0.025 | 0.015 |

| L485Q/X70Q | 0.18 | 0.45 | 1.8 | 0.025 | 0.015 |

| L555Q/X80Q | 0.18 | 0.45 | 1.9 | 0.025 | 0.015 |

10.Physical Properties See table B1/B2

| B1 | ||||

| Tensile Test for PSL1 steel pipe | ||||

| Steel Grade | Mpa Min. | |||

| Yield Strength | Tensile Strength | |||

| L210/A | 210 | 335 | ||

| L245/B | 245 | 415 | ||

| L290/X42 | 290 | 415 | ||

| L320/X46 | 320 | 435 | ||

| L360/X52 | 360 | 460 | ||

| L390/X56 | 390 | 490 | ||

| L415/X60 | 415 | 520 | ||

| L450/X65 | 450 | 535 | ||

| L485/X70 | 485 | 570 | ||

| B2 | |||||

| Tensile Test for PSL2 steel pipe Mpa. | |||||

| Steel Grade | Yield Strength | Tensile Strength | Ratio | ||

| min. | max. | min. | max. | Ratio | |

| L245R/BR | 245 | 450 | 415 | 760 | 0.93 |

| L245N/BN | |||||

| L245Q/BQ | |||||

| L245M/BM | |||||

| L290R/X42R | 290 | 495 | 415 | 760 | 0.93 |

| L290N/X42N | |||||

| L290Q/X42Q | |||||

| L290M/X42M | |||||

| L320N/X46N | 320 | 525 | 435 | 760 | 0.93 |

| L320Q/X46Q | |||||

| L320M/X46M | |||||

| L360N/X52N | 360 | 530 | 460 | 760 | 0.93 |

| L360Q/X52Q | |||||

| L360M/X52M | |||||

| L390N/X56N | 390 | 545 | 490 | 760 | 0.93 |

| L390Q/X56Q | |||||

| L390M/X56M | |||||

| L415N/X60N | 415 | 565 | 520 | 760 | 0.93 |

| L415Q/X60Q | |||||

| L415M/X60M | |||||

| L450Q/X65Q | 450 | 600 | 535 | 760 | 0.93 |

| L450M/X65M | |||||

| L485Q/X70Q | 485 | 635 | 570 | 760 | 0.93 |

| L485M/X70M | |||||

Tel: +86 18202256900 Email: steel@tjdpbd.com