Carbon steel pipe classification

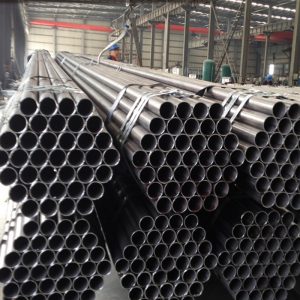

Since the invention of steel, steel pipe manufacturers in China have produced different grades of steel pipe depending on the applications. This is done by varying the amount of carbon of steel. Generally, steel recipes have a weight proportion of carbon in the 0.2% to 2.1% range. To enhance other properties of the base iron, mixtures may also include chromium, manganese, or Tungsten. As a rule, carbon steel depends mainly on carbon to form the durable alloy. Carbon steel may contain other agents such as manganese, cobalt, or tungsten, but the proportion of these materials is not specified. The following shows the four types of carbon steel:

•Mild / low – contain very low percentages of carbon;

•Medium – 0.3 to 0.59% carbon by weight;

•High – 0.6 to 0.99% carbon;

•Ultra high – 1.0 to 2.0% carbon

In the current steel pipe market, carbon steel pipe can be divided into two major categories: hot rolled steel pipe and cold rolled steel pipe. Hot-rolled carbon steel tube is divided into general, low, or medium pressure boiler pipe, high pressure boiler pipe, steel pipe, stainless steel pipe, oil cracking pipe, geological steel pipes and other steel pipe. Cold-rolled carbon steel pipe not only comprises general carbon steel pipe, low pressure boiler pipe, high pressure boiler pipe, steel pipe, stainless steel pipe, oil cracking pipe and other steel pipes, but also includes carbon thin-walled steel, alloy thin-walled steel, stainless thin-walled stainless steel pipe, special- shaped steel. The diameter of hot-rolled seamless pipe is generally greater than 32mm, wall thickness 2.5-75mm. The diameter of cold-rolled seamless steel pipe can go to 6mm, wall thickness can be 0.25mm, outer diameter thin-walled tube to 5mm, wall thickness less than 0.25mm. The dimensional accuracy of cold-rolled is higher than that of hot-rolled.

In the modern times, carbon steel pipe are widely used as structural steel pipe for a wide range of purposes in construction projects. When making a choice for a particular application, there are several advantages of using carbon steel pipe as follows:

1. Safe and Durable

Carbon steel pipe is frequently used because it is durable and safe. Building materials underground may be susceptible to rotting and pests. Carbon steel pipe will not rot and is impervious to pests like termites. Steel also doesn’t need to be treated with preservatives, pesticides or glue, so it is safe to handle and work around. Carbon steel pipe is highly resistant to shock and vibration. Fluctuating water pressure or shock pressure from a water hammer have little effect on steel. Today’s heavy traffic conditions impose much stress on roadway foundations. Carbon steel pipe is practically unbreakable in transport and service, and for this reason it is okay to lay water mains under roadways.

2. Environmentally Friendly

Using carbon steel pipe in your project is not only safer for people, but it is safer for the earth. Carbon steel pipe can be recycled in applications. For example, mild steel pipe can be recycled over and over without losing any strength. Especially in the recent years, every steel pipe manufacturer in China is doing their part to keep the Earth clean.

3. Cost-Effective

For any given pressure, carbon steel pipes can be made much thinner than pipes made from other materials, so they have a greater carrying capacity than pipes of other materials with the same diameter. Carbon pipe suppliers know that their steel pipes are cheaper than copper pipes. The unmatched strength of steel piping increases longevity and reduces the need for replacement and repairs.

Tel: +86 18202256900 Email: steel@tjdpbd.com