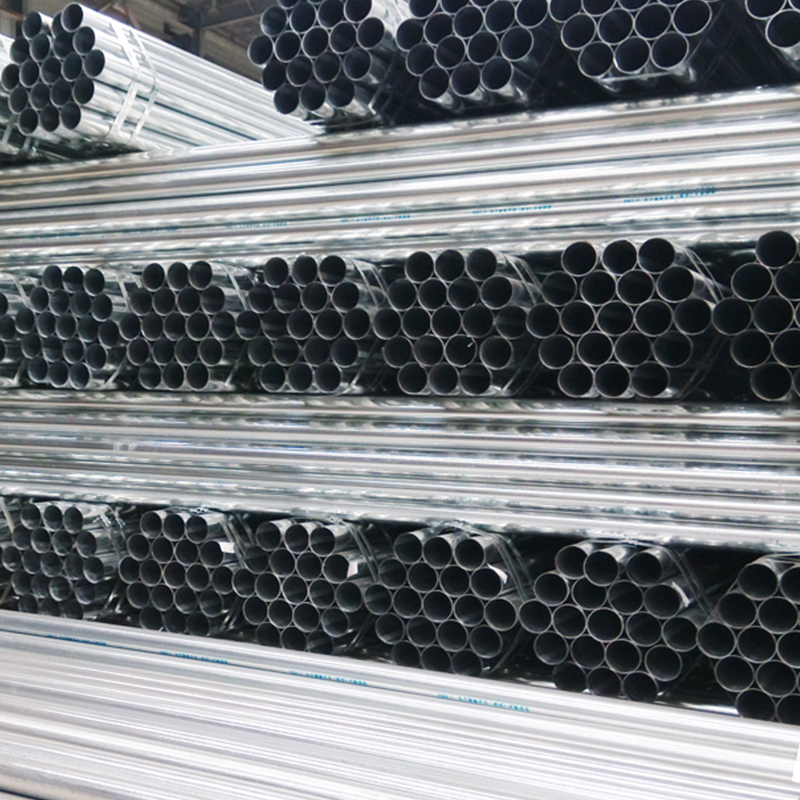

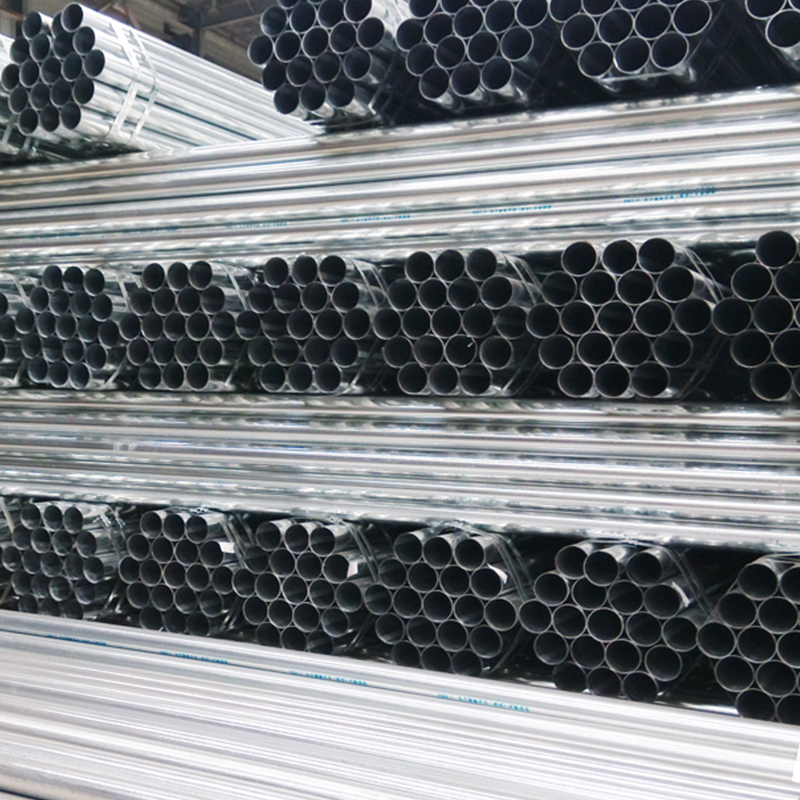

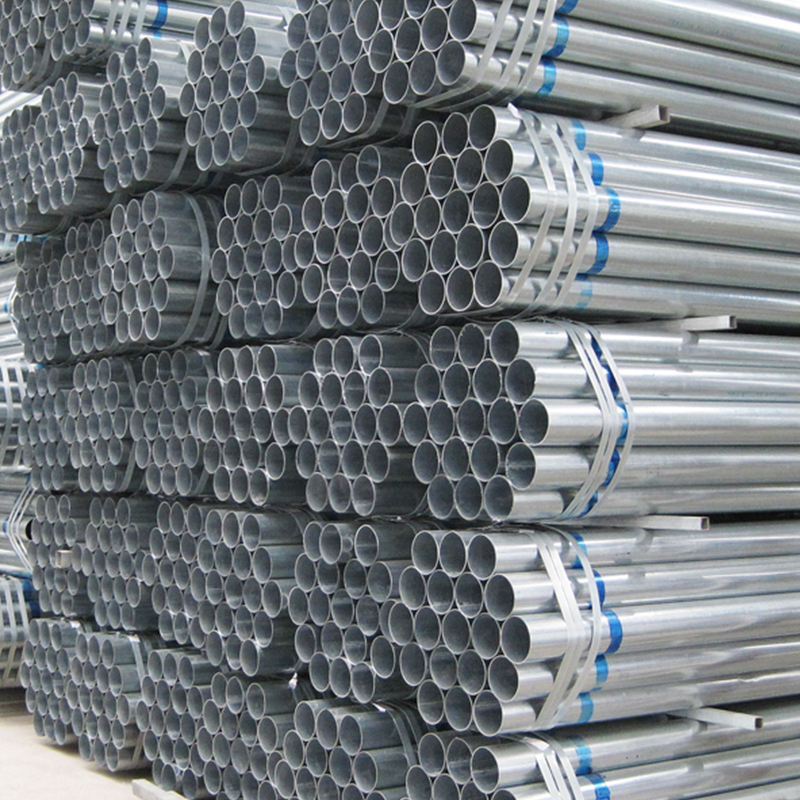

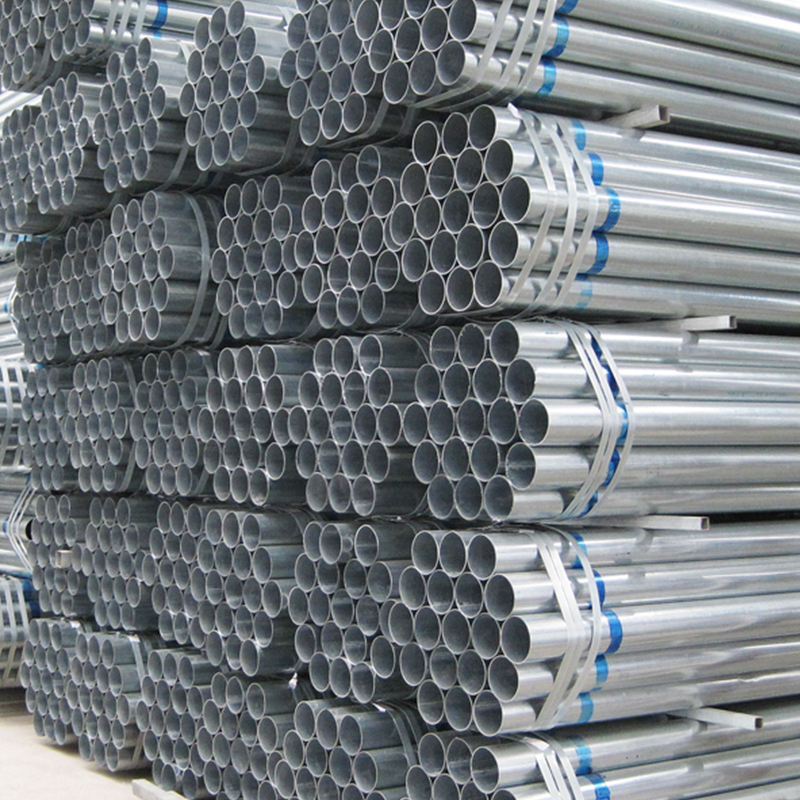

Steel gi pipe, somewhat is considered a superior product in a couple of practical applications, for it extends the service life and has a relatively low cost in use. As a rule, welding of China galvanized steel pipe is done almost exactly the same way as welding of the bare steel of the same composition. The welding industry recognized fifty years ago that welds on galvanized steel and welds on uncoated steel are of comparable strength if the quality of the welds is comparable. In recent years, more and more steel pipe manufacturers begin to pay much attention to the improving the welding technology involving weld toughness, porosity control, weld appearance, restoring corrosion resistance and other issues in a mill.

The difference between welding galvanized steel pipe and welding uncoated steel one is a result of the low vaporization temperature of the zinc coating. Zinc melts at about 900˚F and vaporizes at about 1650˚F. In addition, when it comes to hot dipped galvanized steel pipe, it can not be denied that when zinc vapor mixes with the oxygen in the air, it reacts instantly to become zinc oxide on the surface of pipe to protect steel products from rusting in use. As a rule, welding exposes everyone to similar hazards in most of cases. General hazards of welding include impact, penetration, harmful dust, smoke, fumes, heat and light radiation. Welding “smoke” is a mixture of very fine particles (fumes) and gases. Many of the substances in the smoke can be extremely toxic. The intense heat of welding and sparks can cause burns. Eye injuries have resulted from contact with hot slag and metal chips. The intense light associated with welding can cause eye damage. Ultraviolet light from an arc can cause “welder’s flash” and also skin burns. There is also a danger of electric shock. If combustible or flammable materials are nearby, the heat and sparks produced by welding can cause fires or explosions. The use of compressed gas cylinders poses some unique hazards to the welder.

In certain cases, even though the remaining zinc continues to provide some protection to the zinc-free areas, the appearance is poor, and the zinc-free areas will rust when exposed to the environment. In some cases, paints are properly applied to effectively restoring full corrosion protection to the weld areas. Generally these paints are available in either spray cans or in containers suitable for brush or spray application. However, for certain cold rolled steel pipes, for instance, they exhibit special problems when welding, mostly due to the unevenness of the coating. Edges and corners typically right where welding is being done frequently have very thick, heavy zinc deposits which may interfere with welding much more than where the zinc has been applied evenly. In addition, hot dipped products typically have rough finishes which do not top coat very well, and top coating, especially with powder topcoats, has to be done within 48hours to avoid difficulty with white rust formations.